|

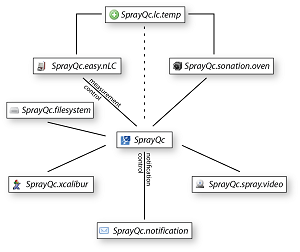

SprayQc.sonation.oven

To achieve high quality chromatography and stable retention times, the temperature of the column can be stabilized with a column oven. We

use a Peltier element cooled and thermo element heated ‘oven’, which enables a constant and controllable temperature environment for short

or long columns. At the start of the measurement, the actual temperature of the column oven is recorded and during the

measurement the recorded temperature value cannot deviate more than 0.5 °C from the starting value. This deviation is much higher than the

accuracy with which the temperature can be controlled by the column oven and below the point where the fluctuations start to affect overall

chromatography.

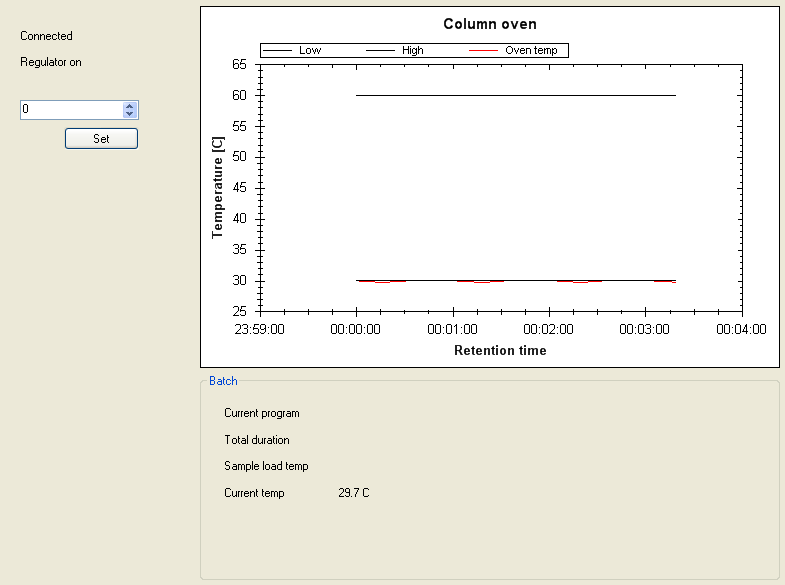

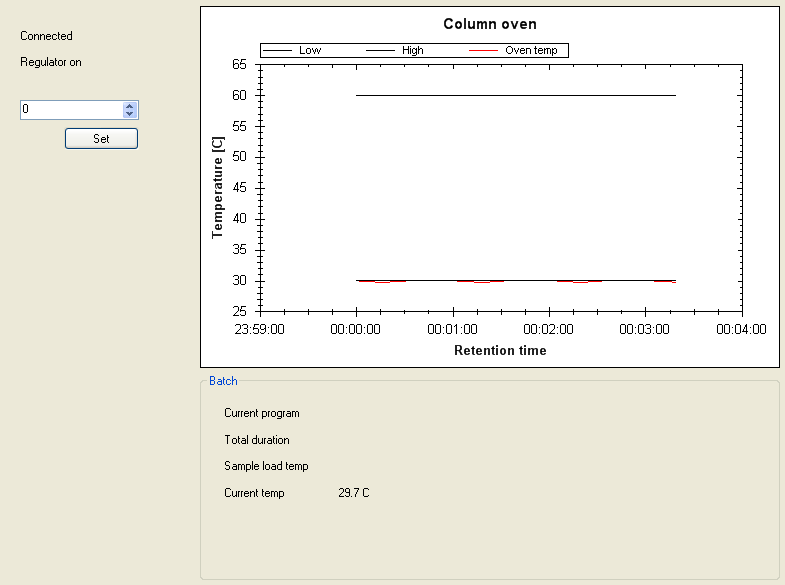

This view provides information on the liquid chromatography device.

- A | Connected

When this is black the column oven software has a connection to the oven. When greyed out not.

- A | Regulator on

When this is black, the temperature is controlled by the column oven. When greyed out not.

- B | Column oven

This graph displays the current temperature (solid red line), the desired temperature (lower black solid line) and the maximum allowed

temperature (upper black solid line).

- Batch (C) | Current program

The filename of the temperature program that is currently being executed by the plugin. When a temperature program is running, no other

process can access the temperature service.

- Batch (C) | Total duration

The time in minutes for the duration of the program. The start-time is linked to the start of the gradient.

- Batch (C) | Sample load temp

The temperature to use during the sample load as programmed in the method.

- Batch (C) | Current temp

The current temperature of the column oven.

| Temperature gradient editor |

|---|

With this view a temperature program can be created. The cells in the table in panel A are fully editable by double-clicking on the

values. This excludes the total time, which is calculated based on the entered time values.

- A | Temperature gradient program

This panel provides the gradient in values. For a graphical overview see panel B.

- B | Temperature gradient

This panel provides the graphical overview of the setup defined in panel A.

- C | Sample load

The temperature to use during sample load.

- D | Stable temp

The temperature to use when the program does not provide further information (e.g. when the LC gradient is longer than this program).

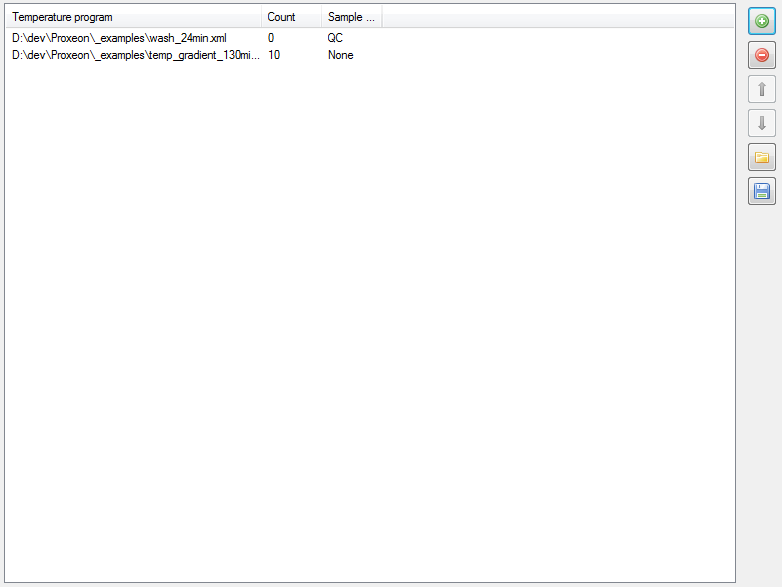

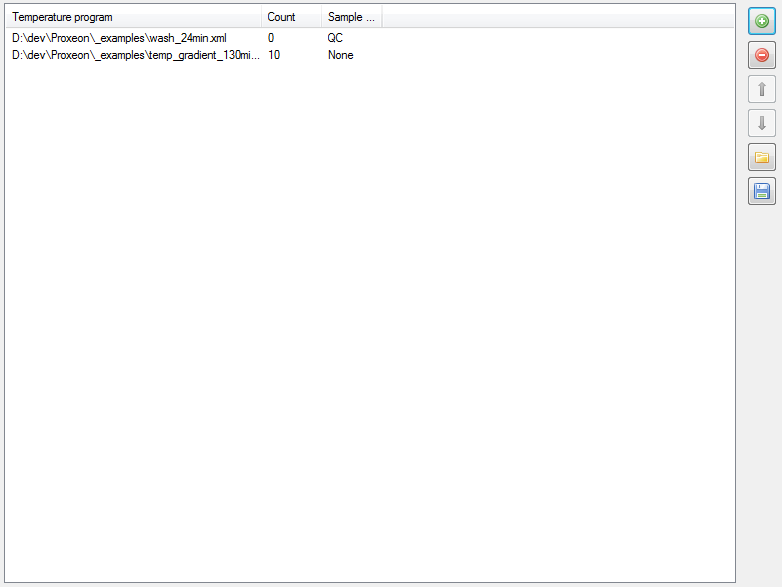

This view enables batch-control of the temperature programs. Each temperature program can be defined to be run for specific sample-types

(as detected by the SprayQc.filesystem plugin) or to be repeated a fixed number of times. The sample-type has precedence over the repeat

count.

- A | Temperature program

The temperature program as defined in the temperature program editor of this plugin.

- A | Count

A repeat count.

- A | Sample type

A sample-type for triggering as defined in the filename.

|

|

Adds a new entry to the end of the list. The values can be edited by double-clicking on the value.

Adds a new entry to the end of the list. The values can be edited by double-clicking on the value.

Removes the currently selected entry from the list.

Removes the currently selected entry from the list.

Moves the currently selected entry one position up in the list.

Moves the currently selected entry one position up in the list.

Moves the currently selected entry one position down in the list.

Moves the currently selected entry one position down in the list.

Opens a saved temperature program.

Opens a saved temperature program.

Opens a file-dialog to save the currently edited temperature program.

Opens a file-dialog to save the currently edited temperature program.

Add a new entry to the batch list.

Add a new entry to the batch list.

Remove the currently selected entry in the batch list.

Remove the currently selected entry in the batch list.

Move the currently selected entry one position up in the batch list.

Move the currently selected entry one position up in the batch list.

Move the currently selected entry one position down in the batch list.

Move the currently selected entry one position down in the batch list.

Load a saved batch list.

Load a saved batch list.

Save to the current batch list to a file.

Save to the current batch list to a file.