|

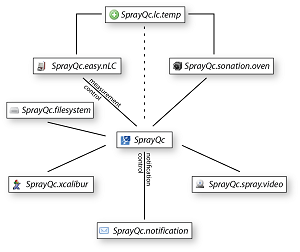

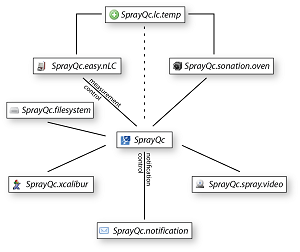

SprayQc.lctemp

This plugin combines the SprayQc.thermo.nLC and SprayQc.columnoven plugins to dynamically react to changes in either. This plugin only

has a settings view. The same functionality can also be achieved with temperature programming; however, this interface provides a more

convenient manner of achieving the defined triggers.

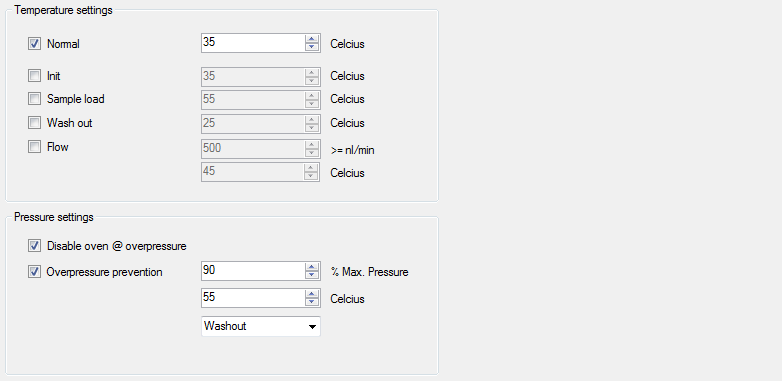

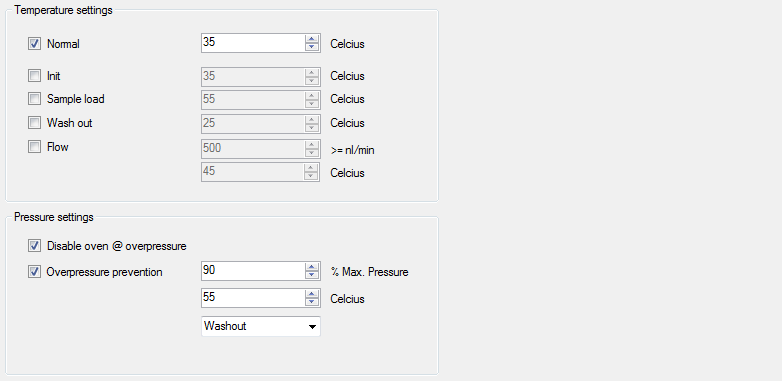

This view provides an overview of the settings.

- Temperature settings | Normal

The temperature to use during normal operation, when no other triggers are active.

- Temperature settings | Init

The temperature to use during the init phase of the chromatographic run. This should be used in conjunction with sample load (see next entry) to ensure that the temperature is at the correct value when sample load commences.

- Temperature settings | Sample load

The temperature to use during sample load. To ensure the oven has enough time to reach this temperature, use this in conjunction with the init.

- Temperature settings | Wash out

The temperature to use during the washout phase. This phase is defined in the SprayQc.easy.nLc settings view as the maximum percentage of buffer B before the washout starts.

- Temperature settings | Flow

The temperature to use when a minimum flow-rate has been reached. This can help to reduce overpressure at higher flow-rates in the gradient.

- Pressure settings | Disable oven @ overpressure

When this is checked, the column oven will be disabled when SprayQc detects overpressure on the nLC device. When this occurs all flow to the column is stopped and the column will dry out (effectively destroying the column) in the elevated temperature of the oven.

- Pressure settings | Overpressure prevention

When this is checked, the column oven temperature will be increased when the pressure on at least one of the pumps exceeds the entered percentage of the maximum pressure.

|

|