| Project |

| SprayQC |

| Source |

| Download |

| Documentation |

| FAQ |

| Quick setup |

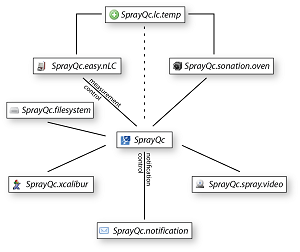

| SprayQc |

| SprayQc.notification |

| SprayQc.filesystem |

| SprayQc.video |

| SprayQc.easy.nLC |

| SprayQc.sonation.oven |

| SprayQc.lctemp |

| Metrics |

| Tutorials |

| Plugin development |

A real-time LC-MS/MS quality monitoring system

SprayQc continuously monitors the status of the peripheral equipment to ensure that operational parameters are within an acceptable range. SprayQc is composed of multiple software components that use computer vision to analyze electrospray conditions, monitor the chromatographic device for stable backpressure, interact with a column oven to control pressure and ensure that the mass spectrometer is still acquiring data. Action is taken when a failure condition has been detected, such as stopping the column oven and the LC flow as well as automatically notifying the appropriate operator. Additionally, all defined metrics can be recorded synchronized on retention time with the MS acquisition file, allowing for later inspection and providing valuable information for optimization. Despite the care taken to develop the SprayQc environment together with the individual plugins and the extensive testing of the software in our laboratory it can happen that the application stops due to an error. It is extremely unlikely that this will influence the data acquisition process. We would however like to be notified of these errors, of which a full transcript is written in the directory where the SprayQc application has been installed. Please send the file ('crash_report@[TIMESTAMP].txt') to scheltem[at]biochem.mpg.de.| Features |

|---|

| Publications |

|---|

-

SprayQC - A real-time LC-MS/MS quality monitoring system to maximize uptime using off the shelf components

Richard A. Scheltema and Matthias Mann

Journal for Proteome Research Submitted